Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

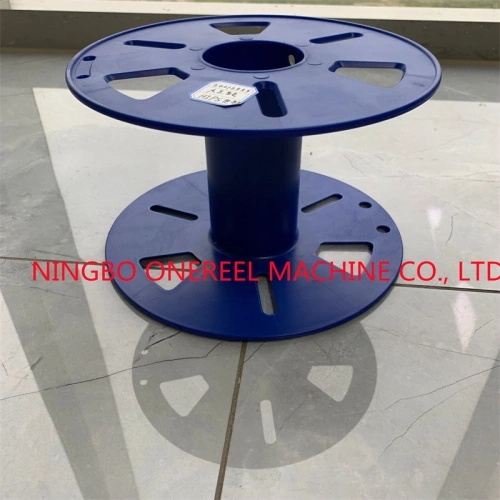

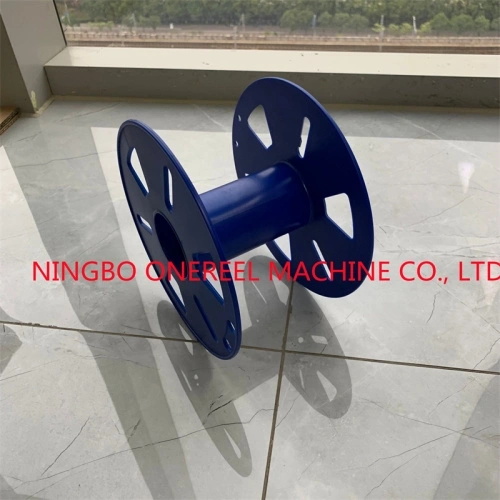

Plastic cable spool is a kind of winding group packaging, because of the particularity of its use, in quality not only strength, size, and weight requirements. Once the requirements are not met, there will be uneven winding, explosion, off cover and other phenomena, causing huge losses to the using unit, so many plastic wire reel manufacturers will make plastic wire reel in accordance with the national quality regulations.

What are the quality criteria of plastic cable spool?

The rotation speed of the plastic cable spool is higher and the tension of the side plate is larger. From the working situation of the wire reel, a qualified wire reel must meet the following quality requirements of plastic wire reel:

(1) In order to ensure uniform winding, the concentricity of the wire reel should be within 0.10mm;

(2) With the increase of the thickness of the wound copper wire, the force on the plates on both sides of the wire reel is increasing. In order to prevent the deformation of the wire reel and the phenomenon of disk burst, the wire reel is required to have a certain strength and rigidity;

(3) As the weight of copper wire at delivery is calculated by deducting the weight of packaging materials after weighing, the weight tolerance of wire reel is very high. For example, the weight of PC10 wire reel is controlled at 500±2g, and the weight of PT90 wire reel is controlled at 3900+30g;

(4) In order to reduce the cost, the user requires that the wire reel can be recycled repeatedly.

The cable tray is not allowed to be mounted horizontally. Lying flat will make the cable winding loose, also easy to damage the cable and cable tray. The power cable is generally wound on the cable tray for transportation, storage and laying.

Short cables of less than 30m can also be rolled into a circle according to the small bending radius not less than the cable allowed, and at least in four bundles before moving. Cable, mining cable in the past, the cable tray is mostly wooden structure, and now it is mostly steel structure, because the steel structure is strong, not easy to damage, and it is very good for the protection of the cable, and the cable tray can be reused, and the economy is better than the wooden cable tray. During transportation, it is important to protect the cables, not just the cables.

November 13, 2024

October 30, 2024

July 03, 2023

July 03, 2023

November 11, 2024

October 15, 2024

September 04, 2023

February 08, 2023

이 업체에게 이메일로 보내기

November 13, 2024

October 30, 2024

July 03, 2023

July 03, 2023

November 11, 2024

October 15, 2024

September 04, 2023

February 08, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.